Metal Recycling in Aerospace Manufacturing

In a world where the demand for aircrafts is soaring higher than ever, metal recycling has become an important part of aerospace manufacturing. With sustainability and reducing waste as goals towards lean manufacturing, companies are looking to minimize their environmental footprint while minimizing losses by incorporating recycled metals into their operations.

Star Recycling partners with aerospace part manufacturers to help them with in the supply chain process, learn how working with us can help your company reduce costs, increase profitability, and tighten the production process.

Capabilities

Scrap metal recycling is an important process in the aerospace part manufacturing industry. By recycling scrap metal, manufacturers can save money on the costs of raw materials and reduce environmental pollution.

We have been working with big and small companies for over 75 years and we have the capability to adequately meet the needs of our clients, tailoring specific recycling programs to meet their specific needs and requirements.

We work with aerospace part manufacturers that generate a large amount of scrap metal during the production process, our team works with companies to valuate and process parts and scrap metal recycling to guarantee proper disposal and to get fair and upfront value for your metals.

Procedures

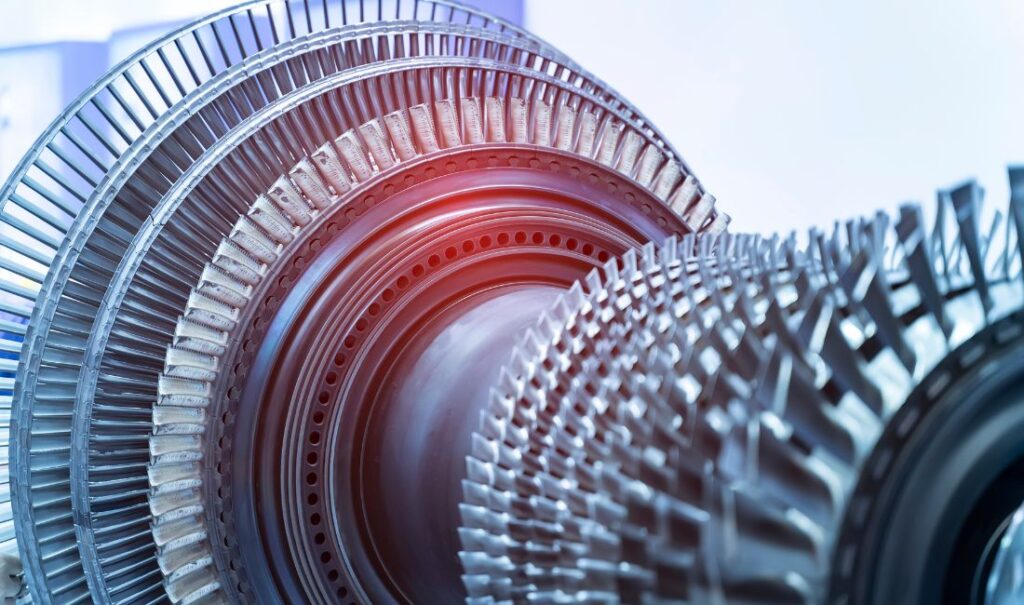

There are many procedures involved in metal recycling in aerospace manufacturing. The first step is to collect the airplane metal scraps once components have been dismantled from the production floor. The material is then transported with bins and trucking services, which we provide to the client within a 24 hour notice. Scrap metal processing begins once the metal scraps are collected, they are sorted into different categories. The most common categories of metals that are aluminum, brass, stainless steel, and titanium. Super alloys and industrial special metals are also commonly identified and found, such as Inconel, Invar, and Monel.

After the metal scraps are itemized and segregated, they are properly documented and evaluated in accordance with the client’s auditing standards. These reports are readily available to the client online or in print.

Metal recycling in aerospace manufacturing is a important process that helps to conserve resources and reduce waste. It is also a great way to create new products from recycled materials and help recover the value of the specialty metals in aerospace parts.

Our recycling programs are here to reduce costs by recovering value that would have been otherwise lost in waste disposal, contribute to tightening operational procedures by repurposing and renewing metals as raw material, and reducing the total amount of waste in production while increasing profitability by 30 to 70% on average.

Contact

For questions relating to any metal, or to enquire about how your company could benefit from our profitable recycling programs, please reach out to an expert at 1-800-700-6382 or info@starrecycling.com.